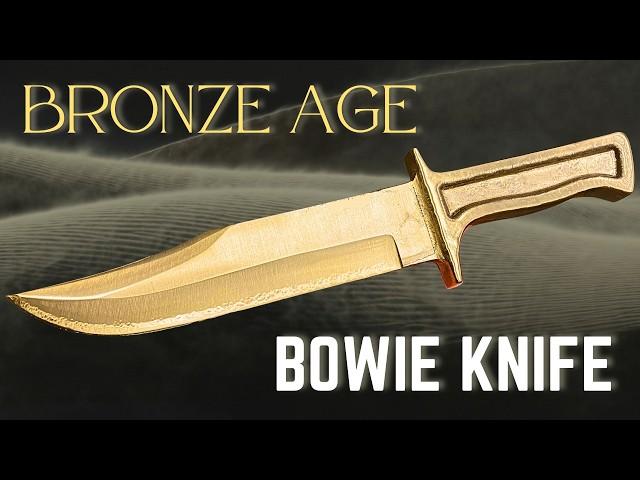

Making a Bowie Knife from Melted Bronze (C-630 Nickel Aluminum Bronze)

Комментарии:

Yes, make a sword from it! Also, do some long-term tests and tell us how it holds up compared to steel. Maybe compare and contrast the cost of the material and how much time it takes to work it into the shape you need versus the same process for steel.

Ответить

Try orienting the mold so the blade is upright if you do a sword. They did that with actual bronze age swords and I don't remember exactly why, but I do remember that Neil Burridge explains it in one of his videos.

Ответить

Nice work brother! Cool experiment! Glad to see your grizzly grinder is still rocking!

Ответить

Not as strong as beryllium copper. Maybe less poisonous.

Ответить

Vhrck out the real findings of Swedish bronze viking swords in the historical museum in stockholm. Those are really affected by time and could deserve nice replicas.

Ответить

Here’s an idea for a project.. 3d print a toroidal propeller and a conventional, cast them, one and compare them for us? Maybe do a crossover with another channel like Drachinifel?

Ответить

Totally corrosion resistant even in seawater. Would make a great diver's knife!

Ответить

SKILLS!

Ответить

I'd love to see you collaborate with Shadaversity on a few blades!!

Ответить

heh choping wood whit a different part off the blade than u cut the paper...

Ответить

Send this to the Dutch Bushcraft knives boys for destruction testing 😂

Ответить

Really cool bro 👍👍

Ответить

Your work was great! All the steps easily shown. You showed us everything. Thank you. Very nice blade.

Ответить

A lot of modern recreation of ancient tools and materials give us the message that our ancestors were actually very clever and came up with very effective tools.

People enjoying these videos may also enjoy Tasting History, an amazing channel.

The fact that you designed the shape of the knife in a 3D computer model means that you have the skills to design other parts. The following might make you some money. In the trailer home maintenance industry, what would be useful, or marketable, is a brass fitting that is 3/8 female fitting at one end and 1/2 inch national pipe thread male on the other end. The 3/8 inch flared female attaches to very old flared 3/8 inch diameter copper. The 1/2 inch un-flared male attaches to a fitting on the end of newer PEX plastic pipe.

Ответить

Do you have any videos with more info on the coffee can sand grinder?

Ответить

To clean files from aluminum use white vinager overnite and baking soda to neutralize

Ответить

So much fun watching you make stuff!

Ответить

Awesome bro. The spear is the king, maybe in the future you would consider creating a " Dory" hoplite spear.

Ответить

Gorgeous piece at the end. Still very impressed with this alloy.

Ответить

Excellent work. It's amazing and looks super nice

Ответить

Nice casting. I’ll try the larger sproul holes maybe that explains some of my castings gone wild.

Ответить

Aluminium*

Ответить

That handle would look sick (and increase functionality) with a dark brown leather wrap

Ответить

Artisan. ✓

Ответить

you should measure the hardness.

Ответить

How would Bronze Age axes, knives etc have been sharpened?

Whetstone??

Super Messer ❤❤❤❤❤❤❤❤❤

Ответить

It took me about week to learn 360

Ответить

Make some guitar strings.....

Ответить

if you file soap stone or chalk with you files before filing metal, any metal, the file will not load up with shavings. it will cut smother and leave a better Finnish too

Ответить

dude I just realized, those risers you put into the mold are like capacitors but for molten metal

Ответить

Hi. Is there a chance to order one? Thank you

Ответить

Would you take 3000 points for it?

Ответить

A little bit of sharpen on stone it would be amazing

Ответить

If you make a longer blade introducing some distal taper and fullering will make it handle and feel a lot better in the hand.

Ответить

So so so good!!! 👍🔥🛠️

Ответить

wow

Ответить

You can load the face of your file with chalk when filing aluminium and that prevents the file clogging up but that saw rasp certainly looks the ticket.

Ответить

I don't know how I found this Channel, but I'm glad I did! 👍🏽😊

Ответить

Drink everytime he says 'extremely'

Ответить

This gentleman is highly skilled with years of training !!!!!!!

Ответить

Why not 3d print the entire thing instead of using aluminum?

Ответить

Actually the best Bowie knives are actually heavy and thick blades and you got to realize they're meant for utility use and you are meant to really use it very rough and hard

Ответить

How do I buy knives from you?

Ответить

You could have added a pinch of scandium to make it super durable without losing any of the other benefits but I could be wrong

Ответить

Great job my boy!

Ответить