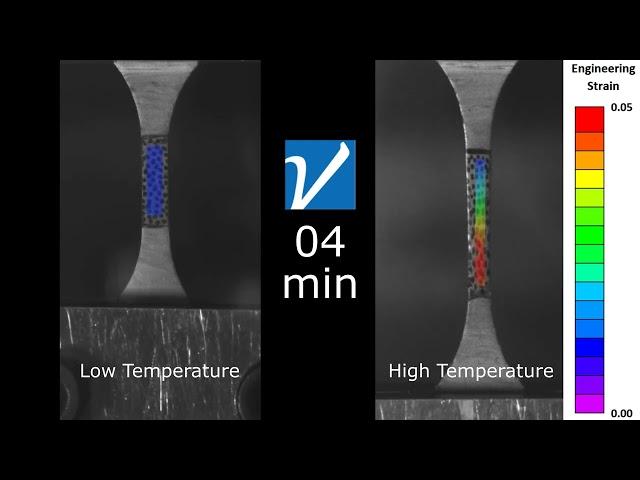

Creep Testing of Polymers with Digital Image Correlation

Polymers are prone to deform slowly over long periods of time when subjected to applied load, a phenomenon known as creep. Over time, the deformation can grow so large that a polymeric part of a device or system no longer functions as intended, leading to product and material failures. This deformation is more pronounced at higher temperatures. Creep testing can be used to assess creep performance and can also be used for material comparisons in selecting the right material for an application.

In this video, Veryst measured creep strain during the test with digital image correlation (DIC) through the viewing window of an oven. Digital image correlation is a non-contact full-field strain measurement technique that can accurately measure large deformations at elevated temperatures, even for very soft materials such as plastics.

To read more about our creep testing capabilities, visit our case studies pages:

https://www.veryst.com/case-studies/creep-testing-polymers-elevated-temperatures

https://www.veryst.com/case-studies/accelerated-creep-testing-polymers-time-temperature-superposition

At Veryst Engineering LLC, we perform both standardized and customized creep testing to meet client’s needs.

In this video, Veryst measured creep strain during the test with digital image correlation (DIC) through the viewing window of an oven. Digital image correlation is a non-contact full-field strain measurement technique that can accurately measure large deformations at elevated temperatures, even for very soft materials such as plastics.

To read more about our creep testing capabilities, visit our case studies pages:

https://www.veryst.com/case-studies/creep-testing-polymers-elevated-temperatures

https://www.veryst.com/case-studies/accelerated-creep-testing-polymers-time-temperature-superposition

At Veryst Engineering LLC, we perform both standardized and customized creep testing to meet client’s needs.

Комментарии:

Creep Testing of Polymers with Digital Image Correlation

VerystEngineering

Narasimha swamy Haadugalu | ಉಡುಪಿನ ರಂಗ ಕಲ್ಲುಕಂಬದಿಂದೋಡಿದ ನರಸಿಂಹ | Bhakthi haadugalu kannada

Jayasindoor Bhakti Geetha

If more to life than meets the eye, what earthly use am I?

Spiritual Unfoldment with John Butler

Поддержка войны и жалобы на жизнь: Двойные стандарты матерей-одиночек

Енот диверсант 01

How to Dress for Prague's WINTER Weather - Tour Guide Life-Hacks

Real Prague Guides

Customer journey: Qué es y cómo definirlo en tu estrategia

InboundCycle - Marketing y ventas inbound

Моя боль - ПЯТЬ ПОСЛЕДНИХ КЛЕТОК

Obsidian Time

Sławkowski Szczyt - Tatry Wysokie [26.09.2021]

A chodźże na pole!

খাজা হায়দার আলী শাহ I haider baba I Haiderbaba786 হায়দার বাবা

Haider Shah | হায়দার শাহ

![Warface: New Update! [Random Box opening] Warface: New Update! [Random Box opening]](https://rtube.cc/img/upload/RTBtY0ttRVFQRGo.jpg)

![Sławkowski Szczyt - Tatry Wysokie [26.09.2021] Sławkowski Szczyt - Tatry Wysokie [26.09.2021]](https://rtube.cc/img/upload/NFZTNEQ0Mk83ei0.jpg)