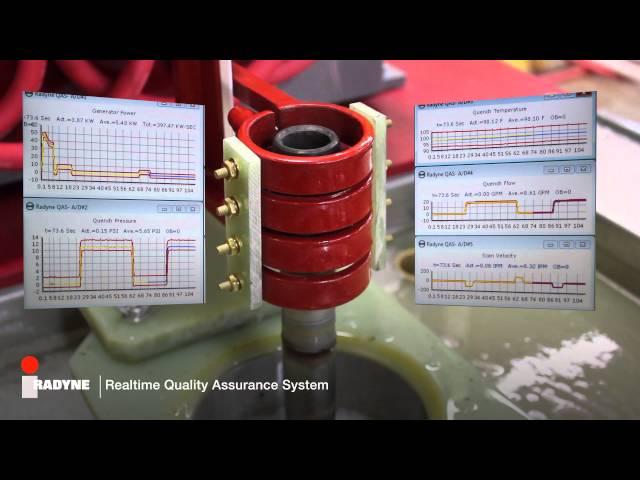

Flexscan Induction Heat Treat Process with Integrated Quality Assurance Signature Monitoring System

The Flexscan® Induction Scanner product line breaks new ground by delivering the most compact, affordable comprehensive heat treat platforms available in the marketplace. This video shows a through hardening and tempering process monitored by the Radyne QAS2000(TM) Quality Assurance Signature Monitoring System. The QAS2000 can be configured to monitor up to 16 channels simultaneously, to capture signatures and alert to deviations from approved signatures. The QAS2000 helps heat treaters maintain quality processes by ensuring that critical process parameters are monitored. Parameters which may be monitored include Quench flow rate, pressure, temperature, power, voltage, current, frequency, energy, torque and many others. Captured cycle process signatures are stored for later reference and can be assocated with jobs and julian date coded. Tooth by Tooth Gear Heat Treating Process signatures can be stored with the specific gear processed. The QAS also connects via ethernet to Radyne's Digital-iQ(TM) based power supplies and can monitor all data channels from these power supplies in addition to the 16 standard channels of data available via it's standard Analog to Digital conversion System.

Learn More about the QAS2000(TM) https://radyne.com/products/qas2000-monitoring-system/

Designed for both pop-up in-place or scan processes, Radyne FlexScan® scanners can be paired with a variety of induction power supplies and coils making a compact, full heat treatment system. The Flexscan can be adapted for different Heat-Treating, Hardening, Tempering, Annealing, Brazing, Soldering, Shrink Fit, Heat Staking and many other applications. FlexScan® Scanners and Pop-Ups are economical, modular, with a range of stadard sizes to support small and large parts. The Flexscan includes Color "Touchscreen HMI, controls, Dual Spindle Lift and Rotate Actuations, Quench subsystem with recirculation pumps, manifold with independent flow adjustment, temperature managment, quench filtering, stainless steel sink and water to water heat exchanger. Options include a variety of base sizes to accommodate different size and weight parts, Extra-large HMI, Integrated Quality Assurance Signature Monitoring System QAS2000(R), Pyrometry, Integrated Vibratory, Rotary or Conveyor Feeders, Pick and Place, Conveyor output and other handling options, and external Water to Air Coolers or Chillers.

Flexscan Induction Heat Treating Machines are easily integrated into larger machine cells with robotic mart loading and unloading.

Learn more about flexscan scanners: https://radyne.com/products/flexscan-induction-scanner/

Learn More about the QAS2000(TM) https://radyne.com/products/qas2000-monitoring-system/

Designed for both pop-up in-place or scan processes, Radyne FlexScan® scanners can be paired with a variety of induction power supplies and coils making a compact, full heat treatment system. The Flexscan can be adapted for different Heat-Treating, Hardening, Tempering, Annealing, Brazing, Soldering, Shrink Fit, Heat Staking and many other applications. FlexScan® Scanners and Pop-Ups are economical, modular, with a range of stadard sizes to support small and large parts. The Flexscan includes Color "Touchscreen HMI, controls, Dual Spindle Lift and Rotate Actuations, Quench subsystem with recirculation pumps, manifold with independent flow adjustment, temperature managment, quench filtering, stainless steel sink and water to water heat exchanger. Options include a variety of base sizes to accommodate different size and weight parts, Extra-large HMI, Integrated Quality Assurance Signature Monitoring System QAS2000(R), Pyrometry, Integrated Vibratory, Rotary or Conveyor Feeders, Pick and Place, Conveyor output and other handling options, and external Water to Air Coolers or Chillers.

Flexscan Induction Heat Treating Machines are easily integrated into larger machine cells with robotic mart loading and unloading.

Learn more about flexscan scanners: https://radyne.com/products/flexscan-induction-scanner/

Тэги:

#Hardening #Induction_Heating #Tempering #Annealing #Brazing #Signature_monitoring #Quality_Assurance_System #Induction_hardening #Induction_Tempering #Quench_and_Temper #Q&T #Induction_Quench #Heat_Treat_Equipment #Heat_Treat_SystemКомментарии:

داستان واقعی : رازهای فاش شده | از خیانت تا عشق با باغبون و دوست پسرم

داستان های واقعی با شبستان

Уже год моему каналу и я решила сделать мини историю.....

Alexandra Pashkevich🙃

فلم کامل هوس باز | بازی با سرنوشت دختر | رسانه مردم New Hazaragi film | People Media

People Media رسانه مردم

طريقة مُجربة 100% لسداد الدين - اسمعها مباشرة من الداعية : محمود الحسنات

الداعية محمود الحسنات القناة الرسمية

ОЧЕНЬ ВКУСНЫЙ КРАСНЫЙ БОРЩ США

Сельчанка в Америке Kids

![[Video Edukasi Anak] Pembelajaran Kelas 1 SD : Cara Merawat Bagian Tubuh [Video Edukasi Anak] Pembelajaran Kelas 1 SD : Cara Merawat Bagian Tubuh](https://rtube.cc/img/upload/UW40cUQyUXhscU4.jpg)